Jeremy, i know that Don Williams,my favorite country singer

has a great example on his website,he also uses a craddle to hold the guitar at level to do the job, while a parallelogram holds the router.

has a great example on his website,he also uses a craddle to hold the guitar at level to do the job, while a parallelogram holds the router.

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Purfling cutters!! http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=5766 |

Page 1 of 1 |

| Author: | Iplaytheoldies [ Tue Mar 21, 2006 2:48 pm ] |

| Post subject: | |

Is anybody still using a purfling cutter? I see that Ibex still makes them. It'a my understanding that they can be difficult to get good results from. I'm going to need something for binding and purfling soon but I can't afford to spend alot on this go around. (Unless I want a divorce) The wood can't wait because I live in a very dry climate that can change from 2% humidity to 100% in a flash and dry right back out again. I thought about making a couple wood router bases that have a radius dish that compliments the radius on the guitar and using a bit and bearing set up and trying it by hand. Maybe someone else has a budget idea that I haven't found yet??? Down the line I will build or buy the nice binding setup, but for number one I'm already over budget. |

|

| Author: | A Peebels [ Tue Mar 21, 2006 2:54 pm ] |

| Post subject: | |

I don't use one, but there has been some talk of them on the forum. Several of the builders have used them quite a bit, and can probably give you some info. Al |

|

| Author: | Serge Poirier [ Tue Mar 21, 2006 3:23 pm ] |

| Post subject: | |

Jeremy, i know that Don Williams,my favorite country singer  has a great example on his website,he also uses a craddle to hold the guitar at level to do the job, while a parallelogram holds the router. has a great example on his website,he also uses a craddle to hold the guitar at level to do the job, while a parallelogram holds the router.

|

|

| Author: | Shawn [ Tue Mar 21, 2006 4:50 pm ] |

| Post subject: | |

I use a purfling cutter all the time ( I build classicals). The term for it is a gramil and they have been used by violin family builders for centuries. When I first started building back in the 70's that was the only tool available so that is how I learned. You can get good results if you take your time and go slowly. It takes a sharp cutter and a light touch as what you are mainly trying to do at first is just barely sever the top grain fibers before cutting to depth. Today I use a modern router based binding machine setup as it is very fast but for something critical I will still use the gramil first to help sever the fibers so that I do not get any chipout. I know it is not necessary but for me it is trusting what I know. It is not hard to make one...the key is getting a good knife. My first gramil was a violin makers knife (single sided bevel) and a couple of wood dowels. At that time in New York city there were alot of Luthiers...it was Eugene Clark that showed how you could do almost anything on a guitar with a knife and a couple of blocks of wood so that is what I copied. At that time Richard Schneider was talking up a really nice German gramil he had found in Europe (similar to the ibex) and LMI sold them but also had a kit which consisted of a cutter (not a great one which is why I used a violin knife) and two blocks of hard maple and a diagram. |

|

| Author: | Serge Poirier [ Tue Mar 21, 2006 5:14 pm ] |

| Post subject: | |

Shawn, do you know where we could get a tutrial on how to build a gramil? I like the idea of severing the fibers prior to cutting the binding channels. sounds like more precautions and safer! |

|

| Author: | Colin S [ Tue Mar 21, 2006 8:43 pm ] |

| Post subject: | |

Yup I'm with Shawn I use a gramil everytime to define the cuts before using the router, avoids tearout especially on WRC tops. I have cut a binding and purfling channel completely with the gramil and chisel method and it is easier than it at first seems and, like bending on a hot pipe, is a skill that should be in your armoury. Easy to make, easier to buy! Colin |

|

| Author: | Serge Poirier [ Tue Mar 21, 2006 11:01 pm ] |

| Post subject: | |

Yeah, i agree Colin, that little tool shouldn't be expensive enough not to buy it. thanks |

|

| Author: | Iplaytheoldies [ Wed Mar 22, 2006 12:32 am ] |

| Post subject: | |

Ebay has the ibex one for around $25. There is occasionally a european model that is made out of solid brass(aside from the cutter) that goes for around $45. |

|

| Author: | Tom Armstrong [ Wed Mar 22, 2006 1:23 am ] |

| Post subject: | |

Serge, I vaguely recall that in one of the Irving Sloane books there are plans and instructions for building a purfling cutter (gramil). I'm on the road right now and can't check it out but maybe someone else could confirm this and maybe post a copied picture of the plan. |

|

| Author: | Mike Mahar [ Wed Mar 22, 2006 1:28 am ] |

| Post subject: | |

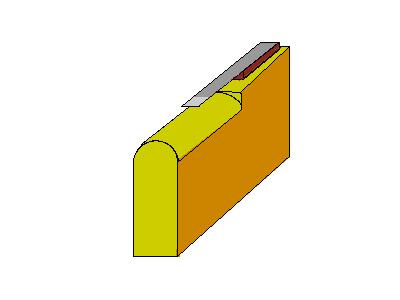

I make a gramil for every binding/purfling combination. I take a block of wood. I round one edge half way, I then take a piece of binding plus a whatere perfling I'm using and glue it to the side of the block. On top of that stack, I glue an exacto blade. I don't remember the number of the blade but it is beveled on one side and has a chisel tip. These gramils match the exact binding and perfiling because that is what I'm using to set the height of the blade.

|

|

| Author: | Serge Poirier [ Wed Mar 22, 2006 4:53 am ] |

| Post subject: | |

Thanks Tom, i'd love to see that plan, when you get back home, please post it! Thanks also Mike for taking the time to draw this sketch. very good tip! Do you glue the blade at a certain angle in order to have the tip of the blade going in the sides at a predetermined length ? |

|

| Author: | crowduck [ Wed Mar 22, 2006 7:20 am ] |

| Post subject: | |

Martin Guitar sells a purfling groove cutter for $32. StewMac has the Sloane cutter for $34, replacement blades are $11. Gramil available from LMI for $45, blades $4. CrowDuck |

|

| Author: | CarltonM [ Wed Mar 22, 2006 7:38 am ] |

| Post subject: | |

[QUOTE=crowduck] Gramil available from LMI for $45, blades $4.[/QUOTE] Should mention that LMI's was designed by Richard Schneider--it's a little more stable and refined than the old Sloane model--and Ron Hock makes the blades! |

|

| Author: | Mike Mahar [ Wed Mar 22, 2006 9:08 am ] |

| Post subject: | |

[QUOTE=Serge Poirier] Thanks Tom, i'd love to see that plan, when you get back home, please post it! Thanks also Mike for taking the time to draw this sketch. very good tip! Do you glue the blade at a certain angle in order to have the tip of the blade going in the sides at a predetermined length ?[/QUOTE] The tool runs along the side of the guitar and I just score the top with it. I don't angle the blade because I want to be able to run the tool "down hill" just like I would a chisel. I use this to score the top just before running the binding channel cutter. I could cut the whole channel with it by making multiple passes. In that case I would set the depth of the cut by mounting the blade so that the cataliver is exactly the right lenght. Or, if I was using a tool that already existed, I'd just make the depth on the blade with a piece of masking tape. |

|

| Author: | Serge Poirier [ Wed Mar 22, 2006 9:27 am ] |

| Post subject: | |

Thanks Mike for your explanations, makes a lot of sense to proceed that way also to sever the fibre lengthwise before trimming, i'm sold! Cool tip! |

|

| Author: | ggdelazzer [ Wed Mar 22, 2006 11:50 am ] |

| Post subject: | |

I use a brass adjustable gramil first and then my router or the Dremel depending on the kind of binding. I use a cutter to sever the grain before routing the rosette channel too. Here are picks of my home made circle cutter, it took less than an hour to make it. With this cutter I can cut both the channel and the same rosette together so the matching is perfect. If you screw any perpendicular guide (or fit a 2 inch wooden pin in a hole) on the lower side you can have also a binding cutter in the same tool. Luigi The complete cutter The upper face The lower face where you can attach an adjustable binding guide Samples of perfect circles cut from veneers |

|

| Author: | Iplaytheoldies [ Wed Mar 22, 2006 12:07 pm ] |

| Post subject: | |

Nice circle cutter!! Any more info about the site? |

|

| Author: | Serge Poirier [ Wed Mar 22, 2006 3:48 pm ] |

| Post subject: | |

Looks like a great tool to have and easy to make!! Thanks Luigi for that great tip, i really like the pin and wheel idea, very cool! By the way, how's your website coming along there bud, need any help? Let me know! Serge |

|

| Author: | jfrench [ Thu Mar 23, 2006 11:36 am ] |

| Post subject: | |

Luigi - Thanks for posting that! I need to make a new circle cutter pretty soon and that'll be very helpful. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|